Spotlight on innovation –The Sinclair brush cover

The packinghouse is a challenging environment for labeling fruit. However, the fruit label is the ultimate minimalist packaging solution to differentiate fruit and provide functional point-of-sale information to consumers – origin, variety, quality – and to retailers – accurate and efficient checkout rings.

The Letdown Brush Challenge

A typical fruit grading line has many moving parts. Fruit moving along the line is washed, graded and labeled before being moved on to its final packing for dispatch to retailers. The high-speed and intensity of production means each of those movements is a potential opportunity for fruit labels to be scuffed off by packing line equipment regardless of how well they are applied.

A typical fruit grading line has many moving parts. Fruit moving along the line is washed, graded and labeled before being moved on to its final packing for dispatch to retailers. The high-speed and intensity of production means each of those movements is a potential opportunity for fruit labels to be scuffed off by packing line equipment regardless of how well they are applied.

One of the most frequent challenges is the letdown brushes. Sinclair labeling systems apply labels accurately but letdown brushes can peel off even the most perfectly applied labels!

The letdown brushes are designed to handle fruit gently, when dropped from the sizer cups, to the transfer belts. Unfortunately, the gentle bristles also do a remarkable job of peeling labels off fruit. Fruit labels on sizer letdown brushes can result in a considerable amount of time and cost being spent to clean the brushes as well as lost production time.

Although not a widespread issue, we know this can be a challenge for some packinghouse operations. Retailers often have a minimum fruit labeling percentage requirement and if not met, deliveries may be rejected. While we have already applied the label to the fruit our teams also want to make sure labeling percentages are consistently high at the end of the packing line. This means identifying challenges along the way and where possible working with customers to mitigate the issue.

The Innovation – Brush Covers

We utilize our 40 years experience in packinghouses working closely with all our customers to customize labeling system installation, and work to continuously ensure high labeling percentages to meet labeling requirements.

Introduced in North America in 2021, the Sinclair Brush Cover is a simple and practical innovation designed to reduce or eliminate labels getting stuck in brushes to maintain industry leading labeling percentages.

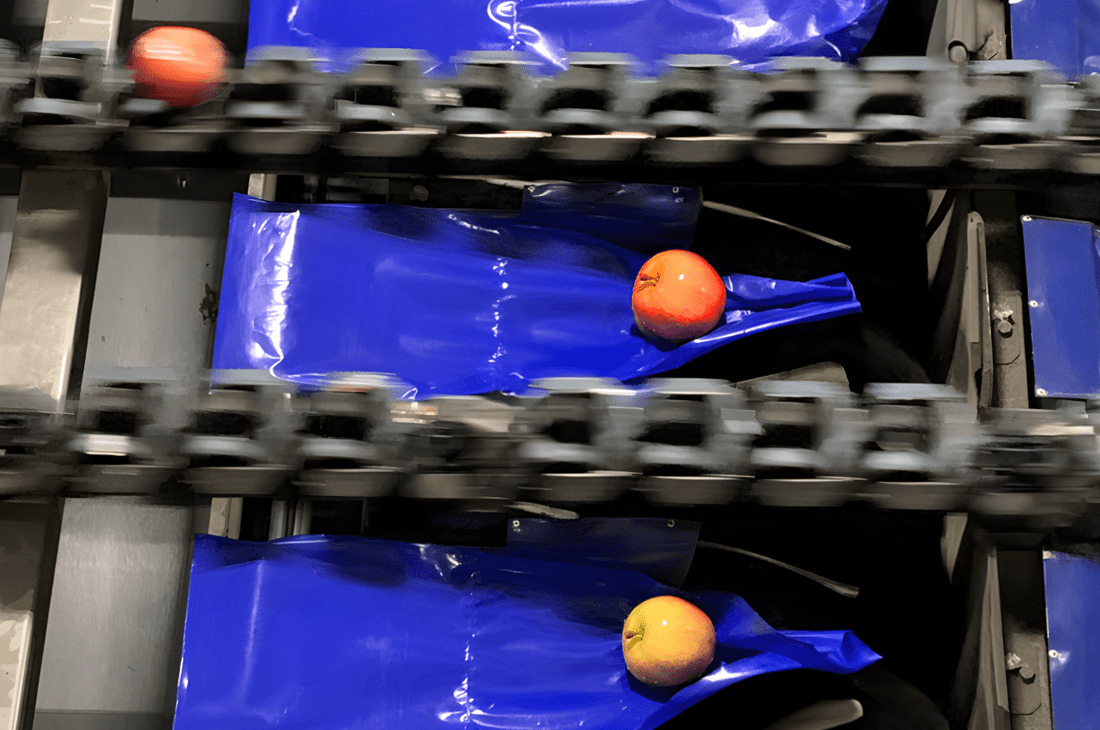

Using field research data and working in partnership with customers, a letdown ‘brush cover’ was designed, manufactured and field-tested. The final brush cover solution sits over the letdown brushes and is cost effective, simple to install, easy to remove and durable enough for packinghouse operations. The brush cover can slip onto the sizer chute and drape over the top of brushes, a snug fit ensures the cover remains secured to the equipment. Installation and removal of the cover is simple, it requires no special tools and no change to the packing line equipment. The brush covers are also recyclable and certified for direct food contact.

Customer Satisfaction

Customer response to the brush covers has been terrific, with packinghouses seeing cleaner brushes, and a significant reduction in cleaning time and cost. The brush cover is flexible enough to conform to fruit and still allow the brushes to gently letdown fruit onto transfer belts, but tough and durable enough for packinghouse rigors.

The Sinclair Brush Cover is now available in North America. Click here to contact your Sinclair Sales Manager to learn more.