EPR is here: How fresh produce packaging choices can cut costs and complexity

Where fruit labels, packaging minimization and compliance meet

Produce packaging choice now carries a price tag beyond materials and shelf appeal – they influence your Extended Producer Responsibility (EPR) fees, compliance risk and brand reputation. If you sell fresh produce, the rule of thumb is simple: the less packaging you use, the less you pay.

EPR makes companies – not taxpayers – pay for the weight of packaging waste that ends up in waste processing plants, so lighter and easier‑to‑process packaging costs less.

That’s why many producers, packers, and retailers are revisiting their packaging choices. Using as little packaging as possible, from easily recycled or compostable materials aligns with EPR and simplifies operations that spread across many markets with varying national legislations.

With minimization in mind, do certified compostable fruit labels offer a practical packaging minimization solution?

Fruit labels can play a practical role in helping producers, packers and retailers optimize EPR compliance. They enable packaging minimization by consolidating essential information—such as branding, traceability details and disposal instructions—onto a compact surface, while still meeting food‑safety and traceability requirements and supporting efforts to reduce food waste1.

The challenge is balancing packaging’s minimum practical requirements (all required product information and branding) with a sustainability benefit. Smart labelling technologies such as QR codes or DataBar, combined with compostable materials, futureproof compliance with upcoming sustainability, traceability and minimization regulations.

Key Insight: How fruit labels can be part of a solution

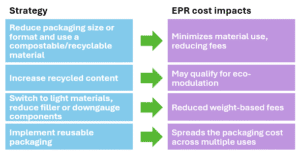

Extended Producer Responsibility (EPR) strategies2

Around 60 countries have proposed or adopted Extended Producer Responsibility (EPR) policies at varying stages and scopes.

The general approach to EPR considers format, weight and material but no two EPR approaches are exactly alike and many are still under discussion. This is due to different:

- local waste and recycling infrastructure

- legal and governance structures

- economic, population densities (available infrastructure e.g. Kansas vs New York) and market conditions

- stage of EPR maturity

However, minimizing fresh produce packaging by using lightweight fruit labels is a practical way to reduce environmental impact and lower potential EPR fees. A fruit label weighs almost nothing compared to most fresh produce packaging – often thousands of times less packaging for the same volume of product. In addition to this a WRAP study in the UK showed that 60,000 tons of food waste could be prevented if all apples, potatoes and bananas were sold loose, representing 8.2 million shopping baskets’ worth of food2. The study also showed 78% of respondents would buy loose fruit and vegetables if they were sold that way.

Fruit labels use around 190× less packaging by weight than other packaging formats for the same produce quantity3. This difference is similar to sending an item in a small envelope rather than in a large shipping box – both can deliver the same item, but one uses a fraction of the material.

Fruit labels and other packaging often serve the same purpose – identification, product information, differentiation – yet the material involved is on an entirely different scale. In an EPR world, that difference is no longer just environmental; it’s commercial too.

Where does EPR exist?

|

EU PPWR key milestones 2026 – 2030

|

EPR rules already exist in the UK, many U.S. states, and other countries. The EU has gone a step further with the Packaging and Packaging Waste Regulation (PPWR), which sets common rules and targets across Europe for reducing, reusing, and recycling packaging. Any company selling products in countries with these rules must follow the local EPR system.

EU PPWR entered into force on the 11 February 2025 Many obligations do not apply immediately as we are in an implementation period (see right for timelines) before the rules start to apply

The current challenges

EPR is in force but has challenges such as:

- fragmented and evolving regulatory landscape, enforcement inconsistencies

- high administrative costs and complexity

- cost pressures and fee structure complexity

- supply chain and waste infrastructure challenges

- differing national obligations creating cross-border complexity

What are the core goals of EPR

EPR goals are to:

- reduce packaging waste and encourage minimization of packaging

- promote circular economy practices through recyclability and reuse

- shift environmental costs onto producers and incentivize sustainable product design

- improve consumer awareness via consistent labelling and transparency

- shift producers to more sustainable materials

Summary

EPR is designed to penalize use of plastic packaging and larger packaging approaches. Compostable fresh produce labels that have ‘finished construction’ certification, not just individual component certifications, offer a practical environmentally conscious opportunity. They minimize packaging weight and contribute to the circular economy as they can safely enter the home or industrial organic waste stream for composting (a form of recycling). EPR policy does need to evolve further to be more supportive of recyclable/compostable packaging outcomes. Certified compostable fruit labels are one packaging solution, but not the whole or full solution given the complexities faced. A practical and environmentally conscious packaging choice, it is a front runner as it also complements, or can accommodate, other needs such as branding, consumer engagement and traceability.

1 Waste and Resources Action Programme (WRAP) article: Label better, less waste: Uncut fruit and vegetables

2 Source data amended from BSI Group article: Extended Producer Responsibility (EPR) Around the World

3 Waste and Resources Action Programme (WRAP) study: Buy loose waste less more half uk adults shopping fresh fruit and veg

4 Sinclair study comprised of packaging types for multiple fruit types from multiple retailers and brands. Packaging was weighed, divided by pack quantity to obtain a comparative weight vs comparative fruit labels weight (i.e. pack of 6 apples – 6 labels needed) using a label size most commonly used for labeling the fruit type based on Sinclair customer data. Fruit label: Average weight of labels 0.018g per pack size → Almost negligible compared to heavier formats. Flexible film wrap & plastic punnet: Average weight 16.36g per pack → ×236% more packaging volume compared to use of compostable labels. Flexible film wrap cardboard punnet: Average weight 20.18g per pack → ×242% more packaging volume compared to use of compostable labels. Netting + Tag: Average weight 2.53g per pack. → ×275% more packaging volume compared to use of compostable labels.